Monthly Archives: August 2024

How to Choose the Right Size Grease Trap for Your Commercial Kitchen

It’s the middle of a hectic Saturday night, your restaurant is buzzing with activity, and the kitchen staff is working at a breakneck pace. Suddenly, the sink backs up, water and grease start to overflow, and what was a smooth operation quickly descends into chaos. This scenario, which every restaurateur dreads, could have been avoided with the right-sized grease trap—a small but critical component of your commercial kitchen.

Choosing the correct grease trap size is a decision that carries significant consequences. Get it wrong, and you could face costly repairs, frequent cleanings, or even health code violations. But how do you ensure you get it right? It’s not just a matter of guessing or opting for the largest model available. There’s a specific process, rooted in understanding your kitchen’s operations and wastewater output, that you need to follow.

What is a Grease Trap and Why is it Essential?

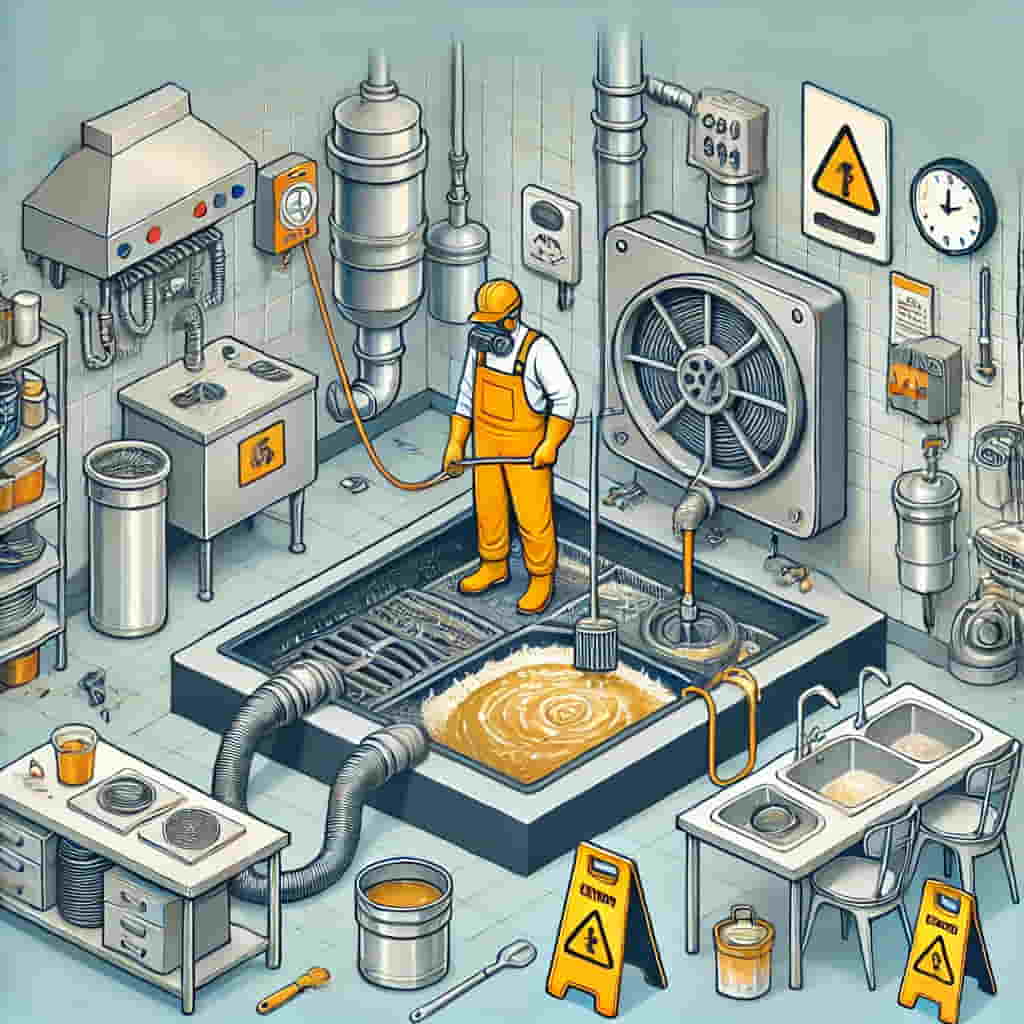

Before diving into the sizing details, let’s take a moment to understand what a grease trap is and why it’s essential. A grease trap (or grease interceptor) is a device that captures and separates fats, oils, and grease (FOG) from wastewater before it enters the sewer system. This process prevents FOG from solidifying and clogging the pipes, which can lead to backups, unpleasant odors, and significant plumbing issues.

Many people might not realize that the grease trap also plays a crucial role in environmental protection. By capturing grease before it enters the municipal sewer system, helps reduce the risk of untreated FOG reaching natural water bodies, where it can cause environmental harm. Improper grease management can lead to the contamination of local water sources, which harms aquatic life by reducing oxygen levels and promoting the growth of harmful bacteria and algae.

For instance, a well-known restaurant in downtown Chicago once faced a significant crisis when its undersized grease trap overflowed during a busy weekend. The trap, unable to handle the volume, caused a flood in the kitchen, resulting in a temporary closure and thousands of dollars in damages. This incident not only disrupted their operations but also led to hefty fines from the local health department. Such scenarios are avoidable with the proper grease trap size and regular commercial grease trap cleaning.

The Importance of Proper Grease Trap Sizing

Choosing the right size grease trap is crucial because it directly affects the efficiency of your kitchen’s wastewater management. An undersized grease trap will fill up quickly, requiring frequent cleanings and leading to potential overflows, while an oversized grease trap may not allow grease to separate properly, causing it to pass through into the drainage system.

One often-overlooked aspect of grease trap sizing is the consideration of future growth. If your business is expanding, or if you anticipate an increase in kitchen activity, it might be wise to choose a slightly larger trap to accommodate this growth. However, this needs to be balanced carefully to avoid the issues associated with oversizing. Another critical factor is the type of food your kitchen prepares. For example, if your menu is rich in fried foods or other grease-heavy dishes, this should be factored into your grease trap sizing.

Sizing Your Grease Trap: A Step-by-Step Approach

Let’s break down the steps involved in sizing your grease trap:

- Calculate Peak Water Flow: Begin by calculating the total water flow rate from your kitchen’s sinks, dishwashers, and other equipment during peak operation times. This is typically measured in gallons per minute (GPM).

- Consider Retention Time: The standard retention time for effective grease separation is about 2 minutes. This means that your grease trap should be able to hold the water produced by your kitchen for at least 2 minutes to allow for proper grease separation.

- Determine Grease Trap Size: Multiply the peak flow rate by the retention time to determine the minimum size of your grease trap in gallons.

Additionally, it’s important to consider the specific plumbing configuration in your kitchen. If your kitchen has multiple sinks or grease-producing equipment, you might need to install multiple grease traps or a more complex interceptor system. Furthermore, local codes and regulations may stipulate specific sizing requirements or limitations, so it’s crucial to check these before making a final decision.

Types of Grease Traps: Which One is Right for You?

There are two primary types of grease traps: passive and automatic.

Passive Grease Traps: These are the most common in smaller kitchens. They rely on gravity to separate grease from water and require regular manual cleaning. While cost-effective, they demand more frequent maintenance and can overflow if not properly sized or cleaned.

Automatic Grease Removal Units (AGRU): AGRUs are more sophisticated and automatically remove grease from the wastewater, storing it in a separate container. They require less frequent maintenance and are ideal for kitchens with higher grease production. However, they come with a higher upfront cost and may be more than what’s needed for smaller operations.

When deciding between a passive grease trap and an AGRU, consider the long-term operational costs, not just the initial purchase price. While AGRUs are more expensive, they can save money in the long run by reducing labor costs associated with frequent cleaning and minimizing the risk of blockages and overflows. Additionally, AGRUs can improve compliance with health regulations, as they often feature automatic monitoring and reporting capabilities, ensuring that your kitchen consistently meets the required standards.

Recent advancements in grease trap technology include more eco-friendly grease removal methods and automated cleaning systems. For example, some modern grease traps feature sensors that alert you when the trap needs to be cleaned or automatically start the cleaning process, reducing the need for manual intervention and ensuring continuous operation. These innovations can be particularly beneficial in busy kitchens where downtime is not an option.

Maintenance: The Key to Long-Term Grease Trap Performance

Even the most perfectly sized grease trap won’t function effectively if it’s not maintained regularly. Routine cleaning is essential to prevent the buildup of grease, which can lead to blockages and system failures. Depending on your kitchen’s volume, you may need to clean your grease trap as frequently as daily, or as seldom as every few weeks.

Regular maintenance isn’t just about cleaning; it’s also about inspection. Over time, the components of a grease trap can wear down, leading to reduced efficiency or failure. It’s recommended to have a professional service inspect your grease trap periodically to ensure it’s in good working condition. Moreover, professional commercial grease trap cleaning services often offer full documentation of their work, which can be crucial for maintaining compliance with local health and safety regulations.

Understanding Local Regulations

Beyond simply installing a grease trap, it’s essential to understand the regulatory environment in your area. Many municipalities have specific requirements for grease trap installation, maintenance, and reporting. Non-compliance can result in hefty fines, business interruptions, or even closure.

Local regulations can vary significantly depending on your location. For instance, New York City requires that grease traps be cleaned and inspected regularly, with documentation kept for at least three years. In California, the regulations might involve more stringent environmental guidelines, particularly concerning the disposal of the waste collected from the grease trap. Checking with your local health department or municipal authority is crucial for understanding the specific regulations in your area. Opting for a reliable commercial grease interceptor service can ensure compliance and help you navigate these regulations effectively.

The Role of Grease Interceptors

For larger operations or those with high grease output, a grease interceptor might be more appropriate than a standard grease trap. Grease interceptors are larger systems, typically installed outside the building, and are designed to handle the wastewater from multiple sinks or appliances.

Grease interceptors are particularly useful in facilities that operate 24/7, such as hospitals or large hotels, where the continuous flow of wastewater would quickly overwhelm a standard grease trap. Moreover, because grease interceptors are installed outside, they also help in reducing odors and improving kitchen hygiene. However, the installation and maintenance costs for grease interceptors are higher, so this solution is generally recommended only for larger or high-volume operations. Regular commercial kitchen grease removal services are essential for maintaining these systems in optimal condition.

Making the Final Decision

Choosing the right grease trap size isn’t just a matter of compliance or avoiding a plumbing disaster; it’s about ensuring the long-term success and sustainability of your business. A well-chosen, properly maintained grease trap will protect your kitchen from costly repairs, ensure a smoother operation, and keep you on the right side of the law.

It’s also important to involve your kitchen staff in the decision-making process. They’re the ones on the front lines who will notice any issues first, so getting their input can be invaluable. Additionally, training your staff on proper grease disposal practices can reduce the load on your grease trap, prolonging its lifespan and reducing maintenance costs.

So, as you consider your options, remember that a grease trap isn’t just another piece of equipment—it’s a vital part of your kitchen’s ecosystem. Take the time to assess your needs carefully, consult with professionals, and invest in a solution that will serve your business well for years to come.